|

A Southern Arizona Coke Oven and Coal Mine

|

At the eastern end of Pinal County, there is a very interesting and different kind of old mine. It was not the usual metal mine, but was a coal mine. Developed in the early 1900s, on a coal deposit that had been discovered in 1881, the mine operators' plan was to produce "coke", an industrial fuel, for the furnaces of a small copper smelter that was nearby.

The photo above, is of the coke oven that was constructed at the mine site. It was in this oven, that the coal was to be roasted and the conversion to coke accomplished. There are other structures around the state that have been described as "coke ovens". Most of those, however, were kilns that burned wood to charcoal, not coal to coke. This coke oven may have been one of the few of this type ever constructed in the state.

In "The Geology and Ore Deposits of the Aravaipa Mining Districts", the author noted the construction of the coke oven. "A coke oven was built near the shaft probably about 1907, and a small amount of coke was produced".

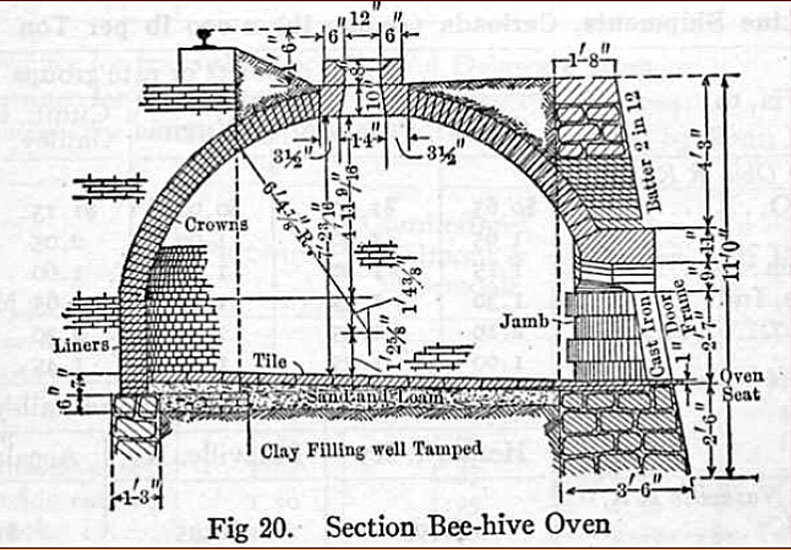

The construction of the coke oven appears to have been very similar to the one in this drawing from "Peele's Mining Engineer's Handbook" that was published in 1918. Peele noted that the form of the "beehive" coke oven had been pretty much standardized.

|

As presented in the diagram above, the domes of the beehive ovens were not left exposed to the open air. Here, only the top is exposed. Coal was loaded into the oven through this opening. A tramway that ran from the mine ended on the ledge to the right.

|

This was not the finished opening in the roof of the oven. The missing parts are resting on the floor below.

|

The diagram of the coke oven shows a cast iron door installed at the side opening. I did not see that there had been a door installed here. Apparently, those were not an absolute requirement. The openings without doors were closed with mud and bricks when the ovens were to be fired. This opening was bit more than 3' tall.

|

The bricks were laid with the short end inward. The thickness of the dome would have been equal to the length of the bricks. Were different types of bricks used to construct this dome? The lower rows seem to have a different coloration. The base of this oven was nearly the 12' diameter as indicated in the diagram.

What happened to have the ring end up on the floor of the oven?

From what I have read, the coal was usually stacked to a depth of around 24" to 36". It was then ignited and the air flow over the pile was controlled by the size of opening left at the side door and the setting of a damper in the chimmey flue. The volatile impurities escaped through the vent while the other impurities formed a slag in the bottom of the oven. In two or three days, the conversion to coke was complete. The exhaust from these ovens was very smoky and not very healthy to breathe....

|

The construction of the side door opening seems very similar to the one in the drawing. The curved bricks used to form the door jambs were not used elsewhere in the structure.

|

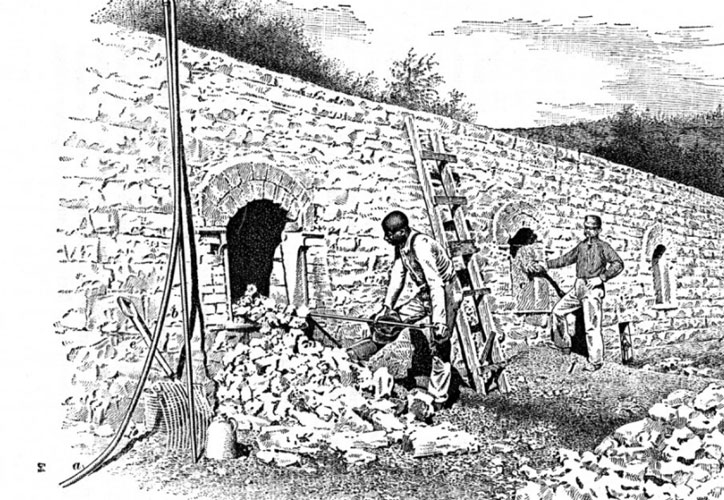

This drawing, posted at www.cokeovens.com shows the "pulling" of a coke oven. The "chunky" material in front of the first oven would have been coke, while the fine material in front of the second oven may have been waste material.

|

Was this a "pulling" bar?

|

The coke would have been pulled out onto the ledge in front of the oven. From there, it may have been loaded into a wagon parked alongside. The "cleanliness" of this site seems to support the statement that only " a little coke was produced".

|

The fire bricks were identified as "LaClede--St. Louis".

|

The main mine shaft was about 60 yards uphill from the coke oven. In this view, the rail bed that had once connected to the oven can be seen to the right. A wagon road is below.

|

In 1903, a USGS geologist was sent out to evaluate the coal field. He took this photo at the mine site.

|

Somewhere along in the mine's history, it became more mechanized. This is the view in 2018.

|

This "locomotive" boiler came from the Atlas Engine Works in Indianapolis Indiana. Atlas was a company known for its boilers and engines. For extra strength, Atlas boilers had double rows of rivets installed along the longitudinal seams. The chimney flue is resting alongside. These are not commonly seen. The boiler still has its internal pipes, which is also unusual. On an early map, a spring several miles away is shown with a pipe connected to a tank. That may have been the source of water for this operation.

|

|

Beyond the boiler are several other pieces of equipment. In this view, there is an air blower, a small hoisting machine and a vertical boiler.

|

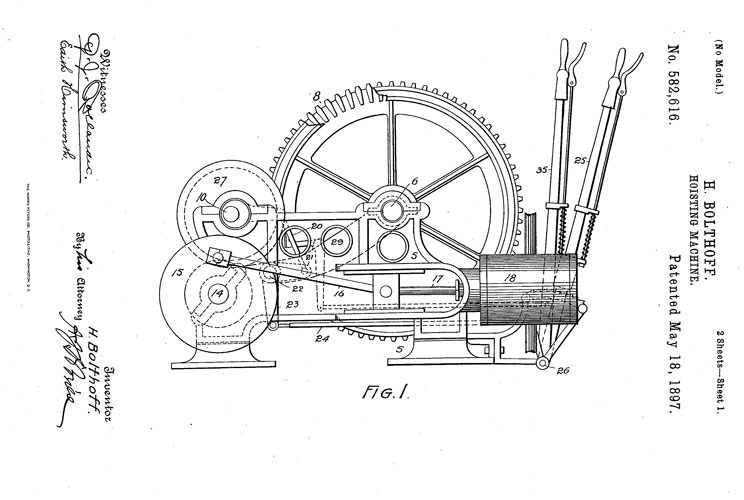

The name of the manufacturer was cast into the side of the hoisting machine. It reads " Hendrie & Bolthoff Mfg & Supply Co Denver Colo" The Patent Date is May 16, 1897.

|

|

When the application was submitted for the patent on the hoisting machine, this drawing was included. I had not realized that the arm identified as "16" was missing from the machine until I compared its photo to the patent drawing. I had seen that arm down at the coke oven, and had wondered what it was.....the patent drawing provided the answer.

|

|

This was an advertisement that was run in the "Jewish Outlook" newspaper in Denver in 1904.

|

The company of Orr & Sembower Inc. was responsible for this vertical boiler. The company dates backs to the 1880s and had plants in Reading, PA and Chicago IL. O & S also produced steam engines. Apparently, many of the boilers produced by this firm are still certifiable and in use today.

|

|

The mine shaft has caved in. One of the few pieces of information available on the mine was that this shaft was 160' deep. The old blower was too close to the edge for me to approach and take a closer look.

|

There are sections of mine rail still in place. An ore car with coal would have been pushed toward the boiler where the track curved to travel down to the coke oven. Cars with waste material would have been pushed toward the photographer's postiion to be emptied over the end of the dump.

|

A dramatic change in the weather interrupted my plans to look around more. The early GLO maps of the area show a wagon road approaching the mine area. Today, only pieces of that road are visible. The early description of the road was that it was suitable for wagon loads pulled by 4 or 6 horse/mule teams.

|

This was the view to the north from below the mine. The vegetation today is Sonoran Desert Scrub. The analysis of the coal, that was done in 1903, found fossils of Sequoia trees.

|

Near a place shown on an early map as the site where a diamond drill had been set up, I came across these old cans. The technique that was used to seal these was used in the early 1900s. I did not get the chance to investigate more to see what else might have been there.

|

So why the limited production of coke from this site? The primary reason was that the coal was not of good quality. Its ash content ran as high as 50%. There was only value if the material could be used locally. In 1907/1908 an economic recession affected the country. The mine and smelter that were to receive the coke closed down. The smelter never re-opened.

The old mine site is on the San Carlos Apache Reservation. Signs at the boundary state that hunting, hiking and camping are permissible with the proper permits. It takes some effort to get those. For me, it is necessary to travel to Globe. There, I purchase the permits at a Circle K store on the north end of town. The Apache rangers are very strict and have been known to confiscate equipment as a deposit towards the settlement of a violation. There are also VERY strict rules prohibiting the use of ATVs on Apache lands....

|